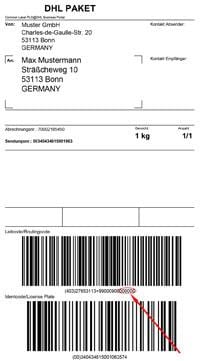

The shipping label must contain two barcodes, the second barcode is the identcode. The shipment cannot be processed without an identification code.

-> Make sure that the identification is included in the routing code.

As your shipping partner, it is important to us to get your shipments to your customers as quickly as possible. To ensure that your parcels handed over to us can be seamlessly handed over to delivery, the shipping labels should contain complete routing coding and should be correctly stuck on the parcels. If this is not the case, the affected shipments must be recoded and reprocessed manually, which can lead to delays and additional charges.

To make the preparations for your parcel shipment as easy as possible, we will show you what you should pay attention to when creating and sticking your shipping labels.

Create your shipping label and make sure that both barcodes are included on it - the identification code and the routing code including the correctly encoded destination address.

Print the shipping label and make sure that the label is printed without any printing errors and that the size of the barcodes and the quiet zones between the barcodes and the edge of the label are maintained.

Stick the shipping label to the largest surface of your parcel and make sure that the label is completely smooth and not covered by strapping or tape.

Stick the label to the largest surface of the parcel, making sure it is completely flat and not covered. See below for more details.

The shipping label must contain both the routing code and the identification code correctly and completely coded so that your shipment can be recorded by machine and processed seamlessly. Prepare your shipments optimally - here you will find the most important examples of why the lead coding can be incorrect.

.

The shipping label must contain two barcodes, the second barcode is the identcode. The shipment cannot be processed without an identification code.

-> Make sure that the identification is included in the routing code.

The shipping label must contain two barcodes, the first barcode represents the routing code. The shipment cannot be processed without a routing code.

-> Make sure that the identification code is included in the routing code.

The routing code must contain both barcodes - identification code and routing code - in full. Otherwise, the shipment cannot be processed.

-> Make sure that the identification code and routing code are printed in full.

The destination address of the shipment must be included in the routing code and must be written and coded completely without errors. Otherwise, the shipment cannot be processed.

-> Make sure that the destination address is written correctly and is correctly and completely coded in the routing code.

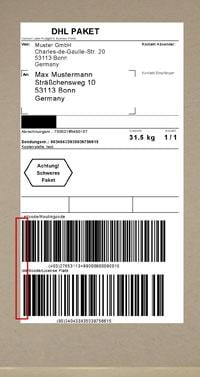

The shipping label must be created without any printing errors and with the correct spacing between the barcodes so that your shipment can be recorded by machine and processed seamlessly. Prepare your shipments optimally - here you will find the most important examples of why a shipping label cannot be read correctly.

The label may not have any printing errors. Otherwise, the label will not be machine-readable.

-> Make sure that the label has good print quality.

The label may not have any printing interruptions. Otherwise, the barcodes on the label cannot be read by machines.

-> Make sure that the label is printed error-free and continuously.

The address field may not be too small. In addition, the specified scaling of the label in terms of size and shape may not be changed. Otherwise, the label will not be machine-readable.

-> Make sure the address field and barcodes are of the correct size. The shipping label should fill the entire area of the template.

The quiet zones of the barcodes may not be violated. The distance to the edge of the label must be at least 5 mm, the distance to the adjacent barcodes at least 7 mm (right + left) or 3 mm (top + bottom). Otherwise, the barcodes cannot be read by machines.

-> Make sure that the quiet zones are observed on all sides of the barcodes.

The shipping label must always be stuck to the largest surface of the parcel so that your shipment can be recorded by machine and processed seamlessly. Prepare your shipments optimally - here you will find the most important examples of why a shipment cannot be recorded correctly.

The label may not be stuck to the front or at an angle. The label cannot be read by machines this way.

-> Always stick the label to the largest surface of the parcel.

The shipping label should not be stuck this way.

The label may not be stuck over a fold/crease and may not be wavy. This would mean that the label cannot be read by machines.

-> Always stick the label completely flat and on a level surface of the parce.

The label may not be covered by adhesive tape or strapping. This would mean the label cannot be read by machines.

-> Always stick the label uncovered to the parcel.

The shipping label should not be stuck like this.

The shipping bag for the label may not be reflective. The label cannot be read by machines through a reflective shipping bag.

-> Do not use a reflective shipping bag to insert your label.